-

Metals [PBF, LMD]

Metals [PBF, LMD] -

Polymers and Composites [FFF, FDM]

Polymers and Composites [FFF, FDM] -

Sintered thermoplastics [SLS]

Sintered thermoplastics [SLS] -

Photosensitive resins [SLA, LCD, DLP]

Photosensitive resins [SLA, LCD, DLP] -

3D scanner for industry

3D scanner for industry -

3D dental scanner

3D dental scanner

Metals

Powder Bed Fusion and Laser Metal Deposition

We offer solutions based on Laser Powder Bed Fusion (PBF) and Direct Energy Deposition (DED), also known as Laser Metal Deposition (LMD), and provide full support for the development of applications with these technologies.

PBF technology uses thermal energy from the laser to melt a section of an object onto a layer of metallic powder. The thermal energy, generated by a fiber laser source, melts the powder, which solidifies as it cools, creating the part layer by layer. This technology enables the production of very thin and lightweight components, which are crucial for industries like Aerospace and Space. It also allows for the creation of complex components with internal cavities and channels that are impossible to achieve with traditional manufacturing methods.

LMD technology uses focused thermal energy generated by a fiber laser source to melt sprayed metal powder at the point where the material needs to be deposited. This way, the laser melts the powder, which is deposited on the component only where it is needed. This technology is suitable for repairing or coating metal parts, adding components to existing objects, and producing large-sized pieces.

Choose the most suitable material for your needs:

Powder Bed Fusion

Prima Additive

Print Genius 150

Great versatility thanks to multi-laser technology.

Powder Bed Fusion

Prima Additive

Print Sharp 150

Designed for R&D applications, it allows the machining of steel, aluminium, nickel, titanium and cobalt chrome alloys.

Powder Bed Fusion

Prima Additive

Print Green 150

Equipped with a green laser, it enables the processing of pure copper, copper alloys and highly reflective materials.

Laser Metal Deposition

Prima Additive

Laserdyne 811

The fastest solution for 3D fabrication, repair and coating with quality and precision.

Do you have a PBF or LMD printer?

Register in the Morphica 3D Marketplace and become our certified supplier.

Register now!Thermoplastics, super polymers and composites

Fused Filament Fabrication

We offer solutions in Fused Filament Fabrication (FFF), also known as Fused Deposition Modeling (FDM), the most cost-effective and flexible technology for producing functional prototypes and, thanks to the performance achieved by super polymers and composites, even end-use parts.

In 3D FFF printing, the material in the form of a filament wound on a spool is first heated and extruded, then deposited layer by layer to create the desired model.

There is a wide range of available materials. From the simpler ones like ABS, PLA, PETG, and Nylon, to more technical ones, such as polymers loaded with carbon fibers and super polymers like, for example, PEEK and ULTEM. These, under certain conditions, can replace more noble materials like metals.

CreatBot

F430 – 420°C Version

Inexpensive yet high-performance FFF 3D printer for fabrications in technical materials (such as ABS, PC, PP, nylon, PEEK).

CreatBot

F160 PEEK

Compact FFF 3D printer for printing high-performance materials such as Nylon, ABS, PEEK or ULTEM.

CreatBot

PEEK-300

Industrial-grade FFF 3D printer for printing high-performance materials such as PEEK and PEI.

CreatBot

F1000

Large-format industrial FFF 3D printer with dual extruder and heated printing chamber.

Do you have an FFF printer?

Register for free at the Morphica 3D Marketplace and become part of our supplier network, earning money with your 3D printer.

Sign up now!Sintered thermoplastics

Selective Laser Sintering

We offer solutions in Selective Laser Sintering (SLS), the ideal technology for small batch productions and large-scale models to be assembled and refined. Components produced with SLS technology have slightly rough surface finishes but almost invisible layers. Reduced costs, high productivity, and materials with excellent mechanical properties make selective laser sintering a very common choice among engineers for functional prototyping, as well as a cost-effective alternative to injection molding for the production of a limited number of components.

Choose the most suitable material for your needs:

Sinterit

Lisa

Reliable and easy-to-use professional desktop SLS 3D printer, ideal for making functional prototypes.

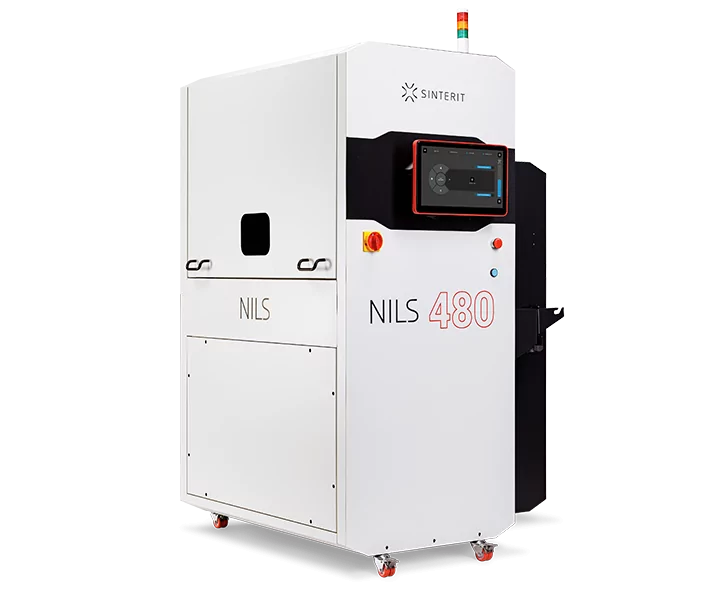

Sinterit

Lisa Pro

Professional high-performance desktop SLS 3D printer, ideal for in-house prototyping of parts with complex geometries and thin thicknesses.

Sinterit

Lisa X

The fastest compact SLS 3D printer on the market, ideal for in-house prototyping of parts with complex geometries and thin thicknesses.

Sinterit

NILS 480

Industrial SLS 3D printer, ideal for companies that want to internalise parts production.

Do you have an SLS printer?

Register for free at the Morphica 3D Marketplace and become part of our supplier network.

Sign up now!Resins

Digital Light Processing

and Stereolithography

We offer solutions based on Digital Light Processing (DLP) and Stereolithography (SLA) technologies and provide full support for the development of applications with these technologies. In both cases, liquid resin is selectively exposed to a light source (a laser for SLA and a projector for DLP) to build up stacked solid layers, ultimately creating a single solid object.

Resin printing is particularly suitable for the production of components and prototypes with high precision, isotropic properties, and impermeability, featuring refined details and a smooth surface finish. Components printed using SLA technology exhibit enhanced resolution and precision, more accurate details, and smoother surface finishes compared to other 3D printing technologies.

Various resins are available:

Phrozen

Sonic Mega 8K

Ultra-high precision 3D printer (43 microns) with large print volume, faster than conventional LCD 3D printers.

Phrozen

Sonic XL 4K 2022

Professional 3D printer designed specifically for the dental sector capable of producing prototypes and models of the highest quality and precision.

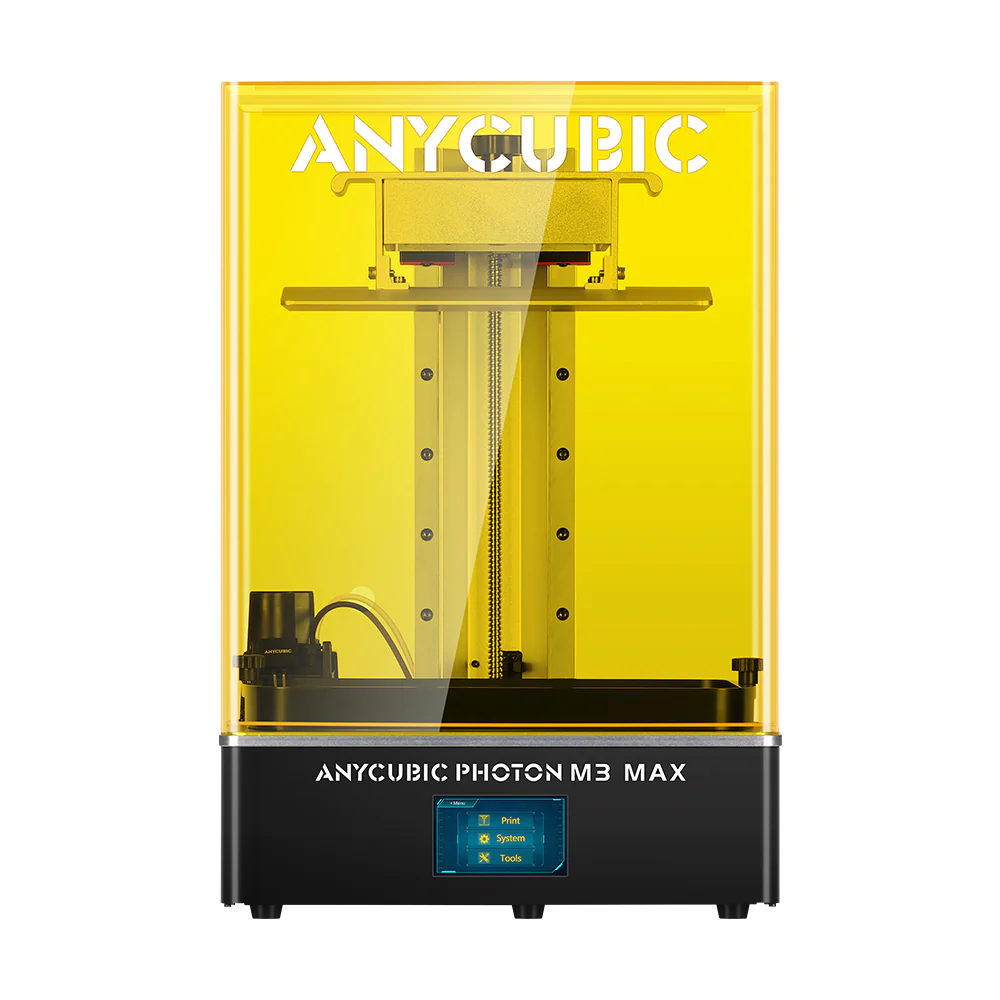

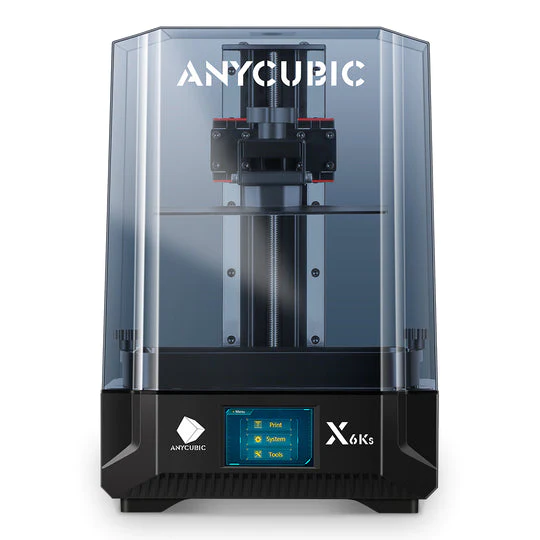

Anycubic

Photon Mono X 6KS

Precise and efficient high-resolution resin 3D printer with large print volume.

Do you have a DLP or SLA printer?

Register for free at the Morphica 3D Marketplace and become part of our supplier network.

Sign up now!Reverse Engineering

3D scanners for industry

Through digital processing combined with additive technology, Morphica is able to perform reconstruction of deteriorated parts and reengineer existing products, improving their performance either in whole or in part.

Do you need to re-engineer a component?

Contact us to request our professional scanning service.

Contact usReverse Engineering

3D DENTAL SCANNER

We offer 3D scanners and solutions for digitization in the dental sector. Digitization in dentistry means faster intervention, high precision, and customized care, with a significant reduction in costs and, above all, time.

Do you want to integrate a 3D scanner into your practice?

Contact us to find out which solution to adopt.

Sign up now!